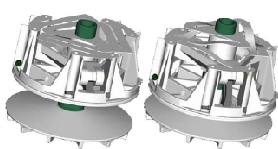

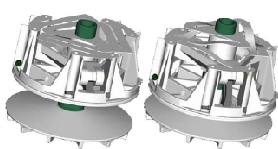

Ortho-planar ATV Clutch Spring

General Information

The ortho-planar ATV clutch spring is a compact spring with a platform that undergoes a large displacement in either direction, but does not rotate like conventional-planar springs. This invention has numerous possible advantages.

- Compact: this planar spring is much more compact than traditional helical springs, decreasing the overall size of the clutch.

- Reduced part count: unlike helical springs, the ortho-planar spring does not require a retaining back plate.

- Easy calibration: since this spring is planar, multiple springs can be stacked for easy calibration. Tuning with helical springs is done by changing the springs, requiring an inventory with a large range of springs.

- Reduced weight: This spring decreases the overall weight of the CVT, thereby also reducing the rotating mass.

- No rotation: unlike conventional helical or planar springs, the center of this spring does not rotate relative to the base perimeter of the spring.

- Low cost manufacturing: the planar nature of this spring allows for low-cost sheet manufacturing processes.

- Reduced wear and noise: because the platform does not rotate or slide against adjoining parts, there is no rubbing or abrasion. This reduces wear and noise.

The Market

CVT clutches are widely used in snow-mobiles and ATVs. They are beginning to gain acceptance in the larger automotive industry. This clutch spring could be implemented in many CVTs in use today.

Patent Information

U.S. Patents 7,338,398 and 6,983,924

Licensing Information

For licensing information, contact the BYU Office of Technology Transfer.

Additional Resources

Rasmussen, N.O., Todd, R.H., Howell, L.L., and Magleby, S.P., "Investigation of Compliant Ortho-Planar Springs for Rotational Applications," Proceedings of IDETC/CIE 2006 as part of the 2006 ASME Mechanisms & Robotics Conference, Philadelphia, PA, DETC2006-99459.

Rasmussen, Nathan, "Compliant

ortho-planar spring behavior under complex loads"

M.S. Thesis, Brigham Young University, December 2005.